Industry Insights: Monitoring Systems in Action

Industry Insights: Monitoring Systems in Action

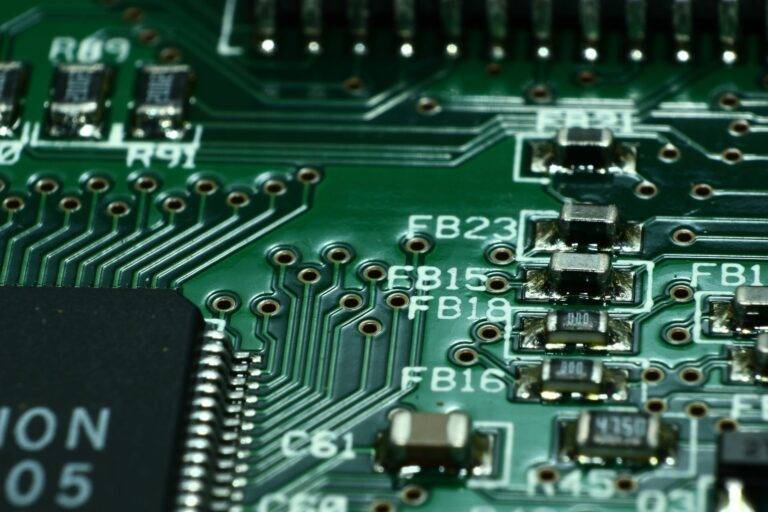

In the modern industrial landscape, the implementation of monitoring systems has become a critical component of operational success. These technologies offer real-time data analytics, enhance safety protocols, and improve overall efficiency. As industries evolve, the adoption of advanced monitoring solutions continues to grow, reflecting their indispensable role in contemporary operations.

The Role of Monitoring Systems in Industry

Monitoring systems are pivotal in ensuring that industries operate smoothly and efficiently. These systems are designed to gather data, analyze it, and provide actionable insights that can be used to optimize processes.

Key Benefits of Monitoring Systems

- Real-Time Data Collection: Enables immediate responses to operational changes.

- Improved Safety: Continuous monitoring can prevent accidents and equipment failures.

- Cost Efficiency: Reduces downtime and maintenance costs by predicting failures before they occur.

For those looking to explore monitoring systems for industries, understanding these benefits can help in making informed decisions.

Applications of Industrial Monitoring Technology

Industrial monitoring technology is applied across various sectors, each with unique requirements and challenges. These applications demonstrate the versatility and adaptability of monitoring solutions.

Manufacturing

In manufacturing, monitoring systems track production lines, ensuring that machinery operates within optimal parameters. This minimizes production delays and enhances product quality.

Energy Sector

The energy sector utilizes monitoring technology to oversee power generation and distribution. This helps in maintaining grid stability and reducing energy wastage.

Oil and Gas

In the oil and gas industry, monitoring systems are crucial for tracking pipelines and preventing leaks. They also play a significant role in corrosion monitoring technology, ensuring the longevity and safety of infrastructure.

Advancements in Monitoring Technologies

Recent advancements in industrial monitoring technology have transformed how industries approach data and analytics. These innovations are paving the way for smarter, more intuitive systems.

Integration with IoT

The Internet of Things (IoT) has revolutionized monitoring systems by enabling interconnected devices to communicate and share data seamlessly. This connectivity allows for more comprehensive oversight and control.

AI and Machine Learning

Artificial Intelligence (AI) and machine learning algorithms are being integrated into monitoring systems to enhance predictive maintenance and automate decision-making processes.

Cloud-Based Solutions

- Scalability: Easily adaptable to growing industrial needs.

- Remote Access: Allows monitoring from any location, ensuring flexibility.

- Data Security: Offers robust security measures to protect sensitive information.

These advancements indicate a promising future for monitoring technologies, offering industries innovative tools to tackle complex challenges.

Conclusion

Monitoring systems are a vital part of modern industrial operations, offering a range of benefits that enhance efficiency, safety, and cost-effectiveness. With continuous advancements in technology, these systems are set to become even more integral to industrial success. By understanding and leveraging these technologies, industries can position themselves at the forefront of innovation and operational excellence.