Proactive Strategies for Steam Turbine Care

Ensuring Efficiency and Longevity in Steam Turbine Operations

In the realm of energy production, steam turbines play a pivotal role. These complex machines are at the heart of many power plants, converting high-pressure steam into mechanical energy that drives generators to produce electricity. However, the efficiency and longevity of steam turbines depend heavily on regular maintenance and timely upgrades. This article explores the critical aspects of steam turbine maintenance, the challenges faced, and best practices that help in maximizing turbine performance and durability.

Understanding Steam Turbine Maintenance

Why Regular Maintenance is Crucial

Steam turbines are subjected to high temperatures and pressures, which can lead to wear and tear over time. Regular maintenance is essential for:

- Ensuring operational reliability and preventing unexpected downtimes.

- Extending the lifespan of the turbine components.

- Maintaining efficiency by keeping the turbine in optimal working condition.

Key Components of Maintenance

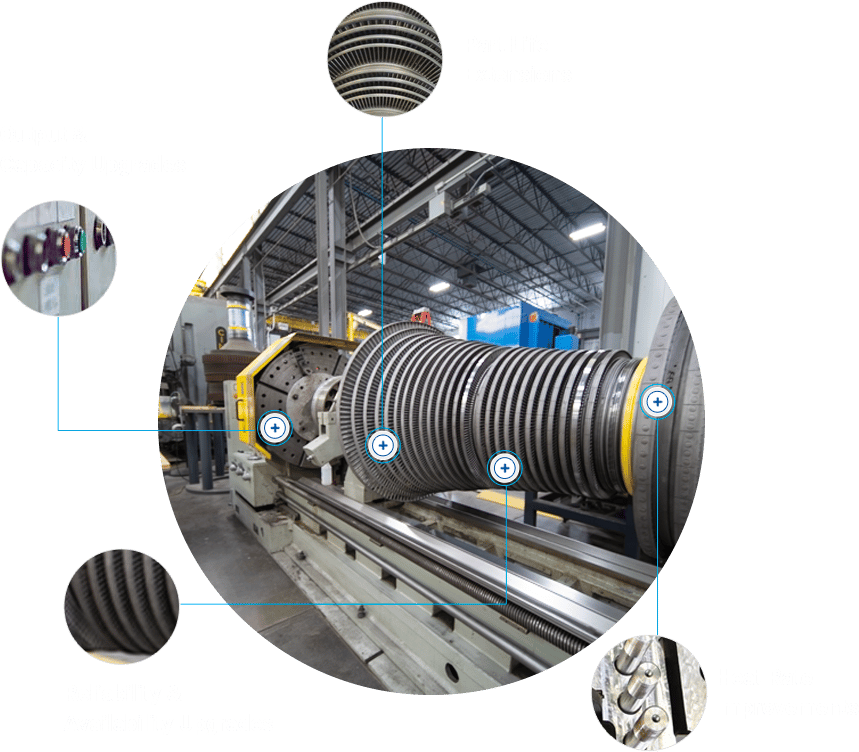

Maintenance strategies can vary, but typically include the inspection, repair, and replacement of critical parts such as:

- Blades and rotors: To check for damage or wear.

- Bearings and seals: To ensure they are protected from the high heat and friction.

- Control systems and sensors: For accurate operation and monitoring.

Challenges in Steam Turbine Maintenance

Despite the best efforts in regular maintenance, several challenges can arise, including:

- High operational costs due to the complexity of the repair processes.

- The need for specialized skills and knowledge to handle advanced turbine technologies.

- Logistical issues in procuring high-quality spare parts and managing downtime effectively.

Best Practices in Steam Turbine Maintenance

Implementing Predictive Maintenance

One of the most effective ways to enhance turbine maintenance is through predictive maintenance techniques. These include:

- Vibration analysis to detect imbalances or misalignments.

- Thermal imaging to identify overheating parts.

- Oil analysis to assess the condition of lubricants and internal components.

Training and Development

Ensuring that maintenance teams are well-trained and up-to-date with the latest turbine technologies is crucial. Regular training sessions can help in:

- Improving the skills of the maintenance staff.

- Keeping the team informed about the latest maintenance techniques and tools.

- Encouraging proactive maintenance strategies.

Conclusion

Steam turbine maintenance is not just about fixing problems as they arise, but about preventing them through strategic, informed actions. By understanding the crucial aspects of turbine maintenance, facing the challenges head-on, and adopting best practices, the energy sector can ensure the efficiency, reliability, and longevity of these vital machines. Implementing a robust maintenance strategy is essential, and leveraging advanced maintenance techniques can lead to significant improvements in turbine performance and operational uptime.